We are Authorised Dealer, Distributor, Supplier, Exporter of Carbide Taps / Industrial Taps / Carbide Industrial Cutting Taps, Spiral Flute Taps, Spiral Point Taps, Hand Taps, Forming Taps, Pipe Taps, Straight Taps, Through Hole Taps, Blind Hole Taps, Machine Taps, Inches Taps, Metric Taps, Roll Taps, Through Coolant Taps, Carbide Taps, HSS Taps, High Efficiency Multipurpose Taps, Straight Flute Taps, Straight Point Taps, Thread Mills, Thread Milling Taps, NPT Taps, NPSF Taps, BSP Taps, BSPT Taps, BSW Taps, ACME Taps, RD Taps, NPTF Taps, Micro Taps, Drill Cum Taps, G Taps, JIS Standard Taps, DIN Standard Taps, ANSI Standard Taps, Special Make Taps, Special Purpose Industrial Taps, Nut Taps, Cut Taps, Bend Shank Taps, Nib Taps, Taps For Fasteners, Threading Taps, Industrial Carbide Toolings, Solid Carbide Cutting Tools (SC Cutters) from Pune, Maharashtra, India.

OSG Taps having no.1 market shareholder.

High Efficiency Multi-Purpose Tap.

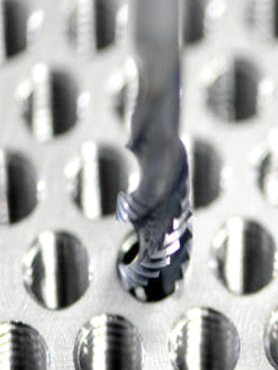

Spiral Flute Taps

- For blind / thru-holes. Ideal for ductile work materials.

- The A-Tap is known for its superior chip evacuation capability. It is an all-purpose tap series developed to accommodate a wide variety of materials and machining environments, helping manufacturers simplify tool management. Looking for a reliable tool that can do it all for general threading? The answer that you have been waiting for is here.

Features

- Sharp cutting edge stabilizes chip shape.

- Variable lead flute enables trouble-free chip evacuation.

- Excels in a wide range of applications and materials.

- Compatible with various types of machining equipment – from manual drilling machines to the latest advanced machining centers.

- New generation synchronized tap holder designed to maximize the performance of your A-Tap tools.

Blind

| A-SFT |

|

| A-LT-SFT |

|

| A-SFT HL | Helicoil / EG / STI M2~M12、No.10~3/8U |

| A-LT-SFT HL | Long Shank for Helicoil / EG / STI M3~M10 |

| A-TPT | Taper Pipe Thread (Long Thread) PT(Rc)・NPT 1/16~1” |

| A-S-TPT | Taper Pipe Thread (Short Thread) PT(Rc)・NPT 1/16~1” |

| A-SPT | Parallel Pipe Thread Rp・G・NPS 1/16~1” |

Spiral / Straight Point Taps

- For thru-holes / work materials that cause chips to curl into coils.

- The A-Tap is known for its superior chip evacuation capability. It is an all-purpose tap series developed to accommodate a wide variety of materials and machining environments, helping manufacturers simplify tool management. Looking for a reliable tool that can do it all for general threading? The answer that you have been waiting for is here.

Features

- Sharp cutting edge stabilizes chip shape.

- Variable lead flute enables trouble-free chip evacuation.

- Excels in a wide range of applications and materials.

- Compatible with various types of machining equipment – from manual drilling machines to the latest advanced machining centers.

- New generation synchronized tap holder designed to maximize the performance of your A-Tap tools.

Through

| A-POT |

|

| A-LT-POT |

|

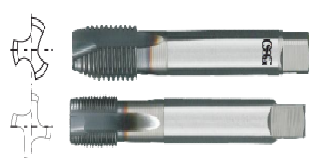

Forming Taps

- For blind / thru-holes. Ideal for ductile work materials.

- The XPF represents a new evolution in forming tap technology. This series is engineered to generate up to 50% less torque versus other forming taps, making it feasible to tap materials up to 35 HRC and sizes up to M45 in diameter.

Features

- Low-torque design for longer life at faster speeds.

- V-Coating for extreme wear resistance.

- Excels in materials up to 35 HRC.

- Sizes available up to M45 for threading of large parts.

X Performer Forming Taps

| Basic form (S-XPF) M1~M45 |

| Basic form (S-XPF) M1~M45 |

| Long shank (LT-S-XPF) M3~M12 |

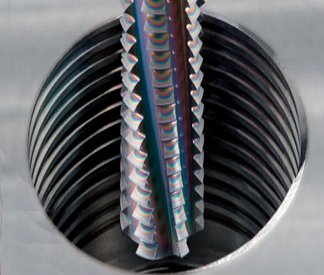

Thread Mill

- Thread mills are tools designed to cut threads by milling. Thread mills are used on numerically controlled machining centers (NC) that have simultaneous, triaxle control and helical interpolation functions. In comparison to general tapping, thread milling is more stable with less cutting condition limitations in terms of chip management and coolant lubricity.

Features

- 1-pass process enables high quality internal threading.

- Right-hand cut and left-hand helix geometry prevents bending.

- Unequal spacing and variable lead flute geometry minimizes vibration.

- EgiAs coating for exceptional wear resistance and toughness.

- Use RPRG to reduce the workload RPRG is the reference value of tool radius offset. Conventionally, the tool radius value is entered during setup as a parameter of the NC system, which is corrected by checking the thread with a gauge. Now, the process of correction can be simplified by simply inputting the RPRG value as indicated on the tool shank.

AT-1

| AT-1 |

|

Authorised Dealer, Distributor, Supplier, Exporter of Industrial Carbide Toolings, SC (Solid Carbide) Cutting Tools